Germany opened the first electric power plant in 1878, and this progress ushered in a new age of energy production throughout Europe. It later came to the rest of the world as well.

The development of the power plants also included introducing nuclear as well as thermal energy. In some cases, fossil fuels were also used, but the exact mode of production differs somewhat. However, while the mode of production may have differed, the ultimate goal was almost always the same, which was to harness the electricity to advance society.

The Need for Skilled Labor

Through the process of storing, creating and distributing electrical energy, skilled labor was at an all-time high. In fact, your average power plant hires anywhere from 400 to 700 power plant workers. This includes both the white collar workers and the blue collar workers.

From there, the type of work they do largely depends on their certifications. The work might range anywhere from operating machinery to metal work to system control to equipment maintenance.

Your average power plant worker will most likely start her career as a non-licensed operator, and eventually, she advances to a licensed operator and can eventually become a senior reactor operator. Normally, these workers will work anywhere from eight to 12-hour shifts per day.

Where the Danger Comes From

Unfortunately, because of how power plants will normally have a bunch of heat-generating equipment and machinery, the earliest installations would often include asbestos in the insulation because of its ability to protect from fires and overheating. In fact, it was standard procedure to add these toxic fibers into the plants where the workers would breathe them. The danger in this substance is how it can cause what’s known as pleural mesothelioma. This is a disease related to asbestos, but because these diseases are preventable, power plant workers have sometimes filed lawsuits against the manufacturers and power plant companies to compensate them for the health dangers.

The Locations and the Products

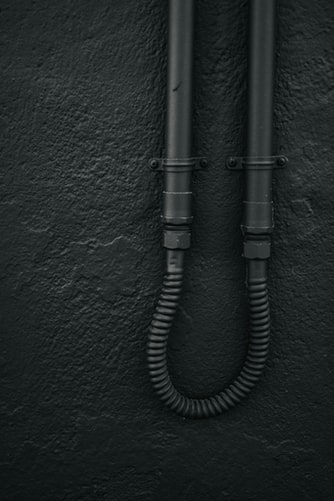

As part of a regular workday, workers would constantly handle these products, which were said to be resistant to heat. They might use a fireproof spray or pipe insulation to protect from fires. Some of the most common areas where you would find these asbestos-related products included:

-

Hot tops

-

Cement

-

Gaskets

-

Blankets

-

Acoustic plaster

-

Pipe coverings

-

Blocks

-

Firebrick

-

Mastic

Asbestos-related products were especially common in the plants that generated electricity and the centers for power distribution. You would also see this carcinogenic contaminant used in outlying workshops, transformer stations and lignite mining plants.

Exposure in the Profession

The power plant workers who ran the highest risk of being exposed to these contaminants were the blue-collar employees because their job would often involve maintaining the pipes or installing them. It could also mean maintaining the electrical appliances of the plant. In fact, some of the records show how asbestos-based insulation was often problematic for these blue-collar workers later in their life. One of the things to realize about this dangerous mineral is how the effects of it didn’t manifest themselves until much later. Sometimes it would take decades before the full effects would come to fruition, which was why it never used to be viewed as harmful.

Workers who were required to saw or cut into some of these products before they installed new asbestos-based materials were especially at risk. Many of the workers would spray this pulp onto some of the heated machinery like the boilers. Meanwhile, some of the others would place insulation on the gaskets, pumps, seals and pipes to protect them. Even if you didn’t handle these products directly, it didn’t mean that you weren’t at risk. In fact, as these contaminants go airborne, it gets into the lungs of anyone who walks by it. To further exacerbate the problem, poor ventilation in these power plants would often circulate the fibers throughout the facility. In today’s world, the hazards are slightly more controlled than what they ever used to be, but the problems still exist where people develop cancer as a result of exposure.

In one of the cases, a previous plant worker, Paul Crane sued the Shoreham Nuclear Power Plant’s general contractor because of how he had spent 11 years wrapping the pipes using asbestos-related materials called Novatex. The New York County Supreme Court ruled in favor of Crane because of how the contractor hadn’t implemented the correct safety procedures. If you or a loved one has developed mesothelioma as a result of careless business practices, you could be entitled to some compensation. When you call a lawyer, he can learn your circumstances to figure out if you have a case.