Around the late 19th century, Ottmar Mergenthaler first invented what we know today as the printing machine.

For its time, this was a highly revolutionary machine because of how it produced an entire line of text all at once. This gave us an amazing boost in existing technology. The printing sector has started to adopt the linotypes as a gold standard for printing effectively.

The Growing Demand for These Machines

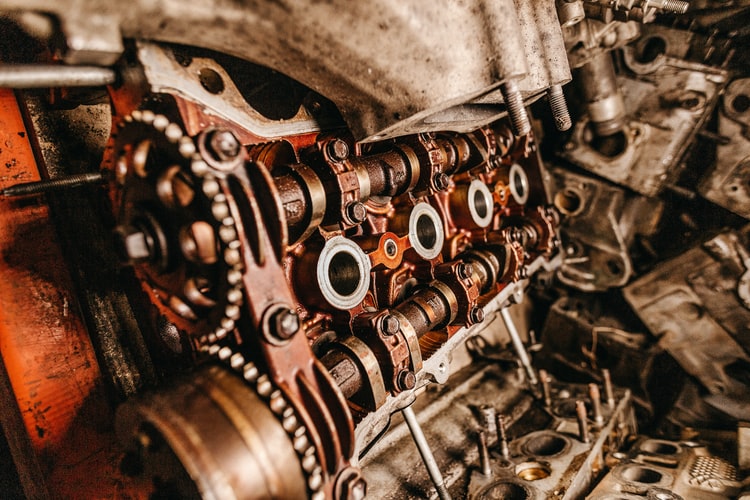

What happened was an ever-increasing demand for the linotype machine, and with this increase in demand for the machines, linotype technicians were soon needed to help with repairing, installing and inspecting the machine. In fact, it was so popular that many of the high production printing companies were soon employing an abundance crew that could keep up with the demand of 50 or more linotype machines. The technicians had a responsibility to maintain these machines. Some of the examples of the tasks they would have to do included adjusting the temperature, polishing it up or making advanced repairs for malfunctioning parts.

Where the Danger Comes In At

Linotypes often contained asbestos-related insulation as a way of keeping the machine from overheating with its internal parts. Unfortunately, these repairs weren’t easy because, during the repairs, a technician could easily disturb the asbestos particles and inhale them, which could cause cancer later down the road. While asbestos doesn’t strike right away, it has been known to cause certain diseases a couple decades after.

Like many of the mechanics during this era, linotype technicians were also at an increased risk of being exposed to these dangers. While this profession may not be among those associated the most with mesothelioma cases, you still have plenty of cases where lawsuits have been filed because someone contracted an asbestos-based disease because of the trade.

The Growth of this Profession

A real demand for these types of technicians hit a plateau during the 1960s. Once the 1970s came around, the profession saw a steady decline in the demand for their work because of the lithograph, which became the preferred method of printing after this time. Long story short, once 1987 rolled around the corner, you couldn’t even find a linotype technician because of how the job description no longer was even part of the Bureau of Labor Statistics’ Occupational Outlook Handbook.

The Products and the Location of the Products

Every linotype manufacturer out there had a different way of manufacturing their products. They might use a different mix of sprays and cement as a way of protecting the metal parts that you could find on the inside of the machine. All of the blends had one thing in common. For example, they were all universal, and they incorporated some level of asbestos-related products in them because of how it kept the machine from overheating.

Asbestos-related cement might be used as a way of insulating the molten lead, which was known as the crucible, and you could find the crucible underneath the pump well. It needed heat if it was going to function. Technicians would often put a jacket of asbestos-related materials onto it.

They wanted to keep the rest of the machine from overheating, and sometimes they would pack the fiber next to the crucibles. In addition, sometimes the technicians would even use an asbestos-based product as a way of protecting the property of the company, and they did this as a way of protecting themselves from burns.

Exposure in the Profession

Technicians did face some level of risk because of the exposure to these carcinogenic fibers. During the process of repairing a machine, the technician would chip away at the existing asbestos-based cement. Another example is when they would remove the crucible from the machine. They would disconnect the wires and then take the pot from the machine using a screwdriver. However, once the technician took the pot from the machine, he would wet down the asbestos-related contaminants into a basin and knead it into a dough. The mixture would be packed into the liner before putting the pot back over to the machine. The asbestos-related fibers would often be left on the surface of the equipment as a result of this work.

David Peterson, one of the people to file a lawsuit for asbestos-related exposure in this field, had worked for eight publishing and printing companies during his time as a technician. He had a variety of roles during his time, but Peterson regularly serviced the linotype machines throughout his career.

Peterson’s legal team helped to link his diagnosis with his professional history, which helped his case. Peterson won his case as he filed a lawsuit that came up against nine of the different asbestos-based manufacturers. If you or someone you love has been injured because of working with these products, you may want to call an attorney.